bopp bags wholesale

| Bag material used | 100% virgin PP |

| Bag color | Can be white,transparent,blue,yellow etc.as per customer's requirements |

| BOPP printing | Max.10 colors |

| Bag width | 25~150cm |

| Bag length | As per customer's requirements |

| Mesh | 7*7~14*14 |

| Denier | 650D to 2000D |

| Fabric GSM | 40gsm~250gsm |

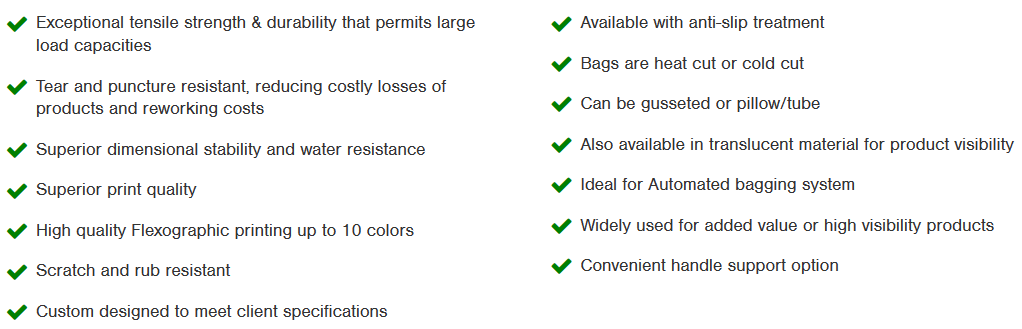

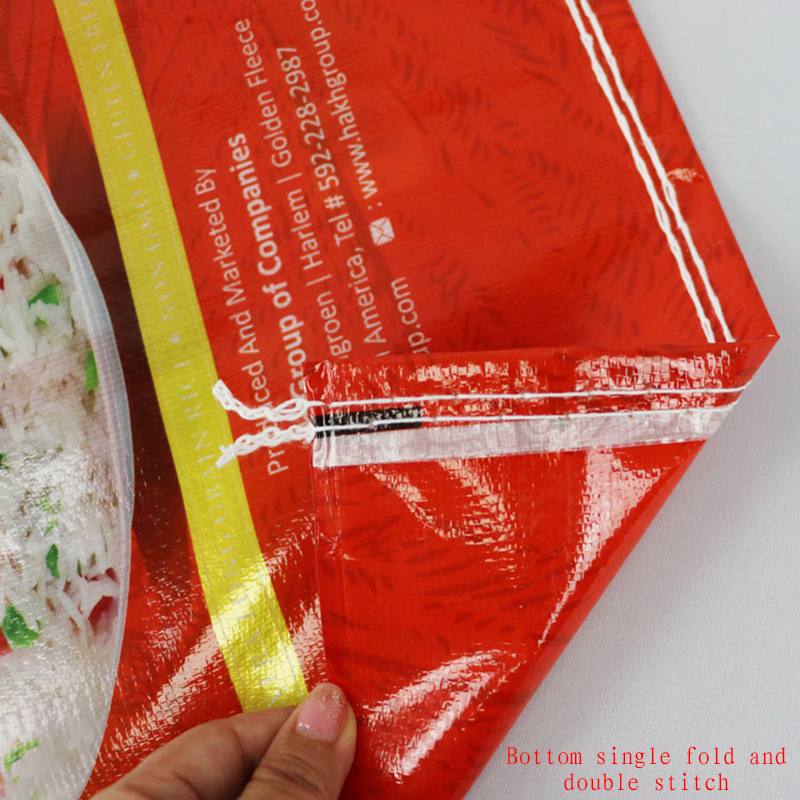

| Bag Top | Heat Cut, Cold cut,Zigzag hemmed,Hole handle cut or other types |

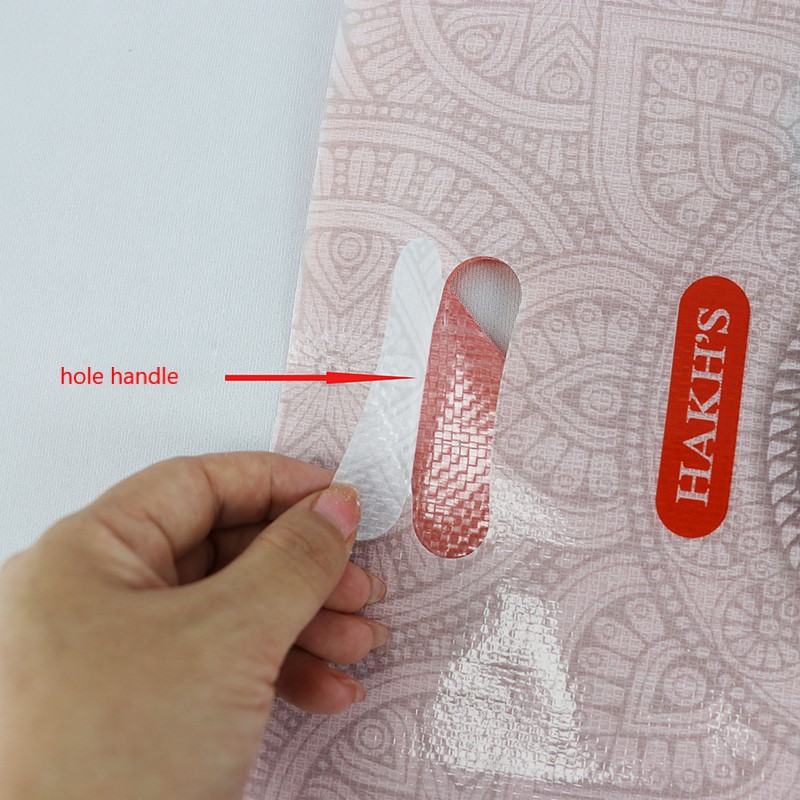

| Bag Bottom | 1) Single fold and single stitched 2) Single fold and double stitched |

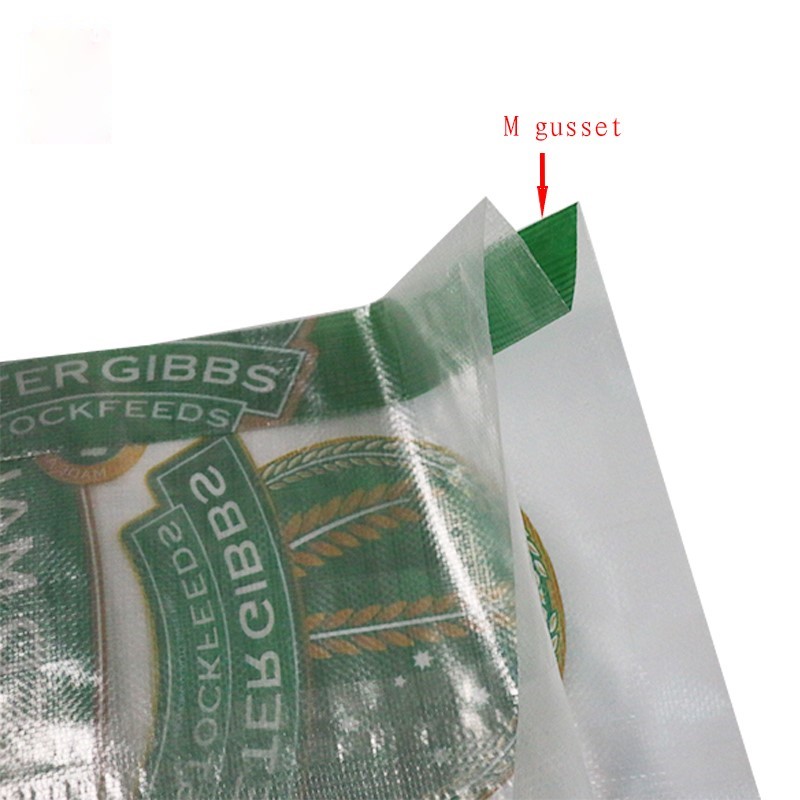

| Special Treatment for the bag fabric | 1) Can be UV treated, as per customer's requirements 2) Can be with M gusset,as per customer's requirements 3) Can be with PE liner inside, as per customer's requirements 4) Can be with micro-perforation,detailed as per customer's requirements |

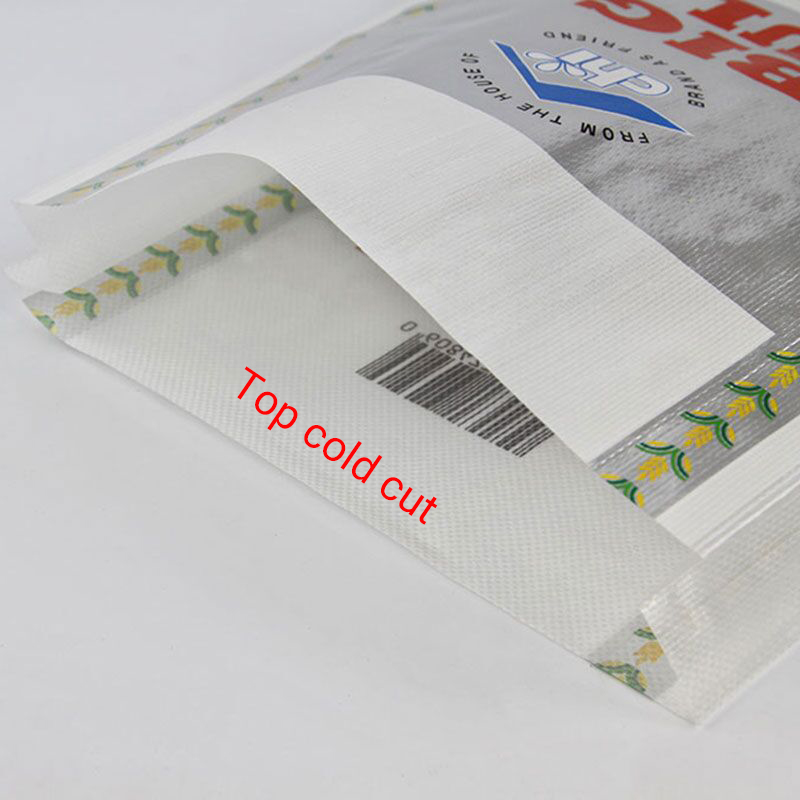

| Bag Surface Dealing | 1) BOPP film printing on one side; 2) BOPP film printing on two sides; 3) No BOPP film printing,only have coating on two sides; 4) Others,as per customer's requirements. |

| Packaging | 100pcs/bundle,1000pcs/bale, or as per customers' requirements |

| MOQ | 5 tons |

| Production Capability | 200 Tons/Month |

| Delivery Time | The first container within 45 days after order confirmed,the later ones as per customer's requirements |

| Payment Terms | 1) 30% down payment by T/T before production,70% balance against copy of B/L; Western Union; L/C at sight. |

| Certification | FSSC22000,ISO22000,ISO9001,ISO14001,SGS, BV, |

| Samples | Samples are available and for free. |

| Factory | Have strong technical strength & Professional service team with more than 25 years production experience |

| Quality Control Certificates | FSSC22000,ISO22000,ISO9001,ISO14001 |

| Machines | We have 4 extrusion machines,more than 200 circular woven machines,hundreds of cutting and sewing machines,general printing and BOPP film printing machines,we also have our own PE liner producing machines and testing machines. |

| Quality and Price | We guarantee all PP bags produced by our factory is high level ones while with reasonable prices,we don’t do one-time business,what we want is long time cooperation. |